Tips and Resources for Building and Running a Manufacturing Facility

Tips and Resources for Building and Running a Manufacturing Facility

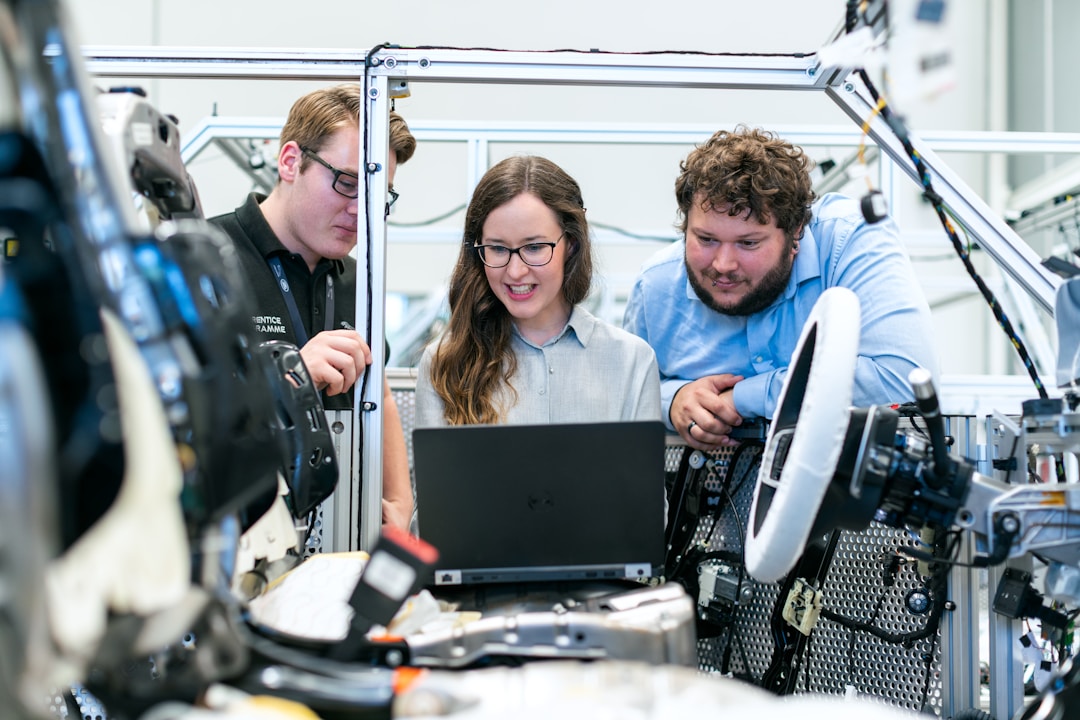

Building and running a manufacturing facility requires careful planning and effective management across various aspects of operations. From selecting the right equipment to ensuring safety standards, every detail contributes to the facility’s success. Below, we will explore key areas that can guide you in optimizing your manufacturing processes.

Essential Tools for Efficient Manufacturing Operations

The foundation of any successful manufacturing operation is selecting the right tools. High-quality machinery and equipment are crucial for producing quality products efficiently. These tools help improve output while reducing downtime and maintenance costs.

One essential tool for improving operations is manufacturing ERP software. This software allows you to manage and integrate core business processes such as inventory, production schedules, and financial data. It helps streamline workflows and ensures alignment across all business areas.

Another important tool is automation technology. Automated systems can handle repetitive tasks, freeing workers for more complex operations. These tools reduce the risk of human error and improve overall productivity.

Lastly, a robust quality control system is essential for ensuring product consistency and meeting customer expectations. This system detects defects using measuring tools, inspection stations, and software. Quality control ensures that each product meets the specified standards before reaching the market.

Navigating Compliance and Safety Regulations in Manufacturing

Compliance with safety regulations is a critical aspect of running a manufacturing facility. Not only does this ensure a safe working environment for employees, but it also prevents costly fines and legal issues. Adhering to OSHA guidelines and industry standards is non-negotiable for any manufacturer.

In addition to general safety regulations, ensuring the facility meets environmental compliance standards is vital. This includes managing waste, emissions, and the use of hazardous materials. A comprehensive environmental management plan can help your facility avoid legal troubles and contribute to sustainability.

Ensuring electrical safety is another key element. To maintain a safe and efficient electrical system, consult a reliable service provider for commercial electrical services. Google “commercial electrical services near me” to find experienced professionals who can help you maintain your facility’s electrical systems and ensure they are up to code.

Regular audits and employee training on safety measures are also essential. Safety procedures, like emergency evacuation plans and equipment handling, must be reviewed frequently to keep the workforce safe. This proactive approach can help prevent accidents and maintain a productive, compliant environment.

Optimizing Workforce Management and Productivity in a Manufacturing Facility

Effective workforce management is vital for maintaining productivity in a manufacturing facility. One of the first steps is to define roles and responsibilities clearly. Ensuring that employees know their tasks and the expectations around them helps to eliminate confusion and increases overall efficiency.

Incentive programs can significantly boost productivity by motivating employees. Rewarding workers for meeting targets or improving processes helps foster a competitive and driven environment. A motivated workforce is likelier to go the extra mile, improving the facility’s overall performance.

Training and development are other crucial factors in optimizing productivity. Regular workshops and skills training ensure employees stay updated with the latest techniques and technologies. Skilled workers can handle more complex tasks and help improve overall manufacturing output.

Lastly, fostering a positive company culture can have a long-lasting impact on productivity. By encouraging open communication and teamwork, employees feel more engaged and valued. A positive work environment leads to lower turnover rates and higher overall performance in the facility.

Overall, building and running a manufacturing facility requires careful attention to tools, compliance, safety, and workforce management to ensure long-term success. By focusing on these key areas and continuously optimizing operations, you can create an efficient, productive, and sustainable manufacturing environment that fosters growth and meets industry standards.